Evolution of Infrastructure Development: From Ancient Civilizations to Modern Megacities of India

Dear adventurers of the past, present, and future, let’s embark on an enthralling journey through time, tracing the remarkable evolution of infrastructure development in India. We’ll unravel the secrets of ancient civilizations like the mighty Roman Empire and the enigmatic Indus Valley Civilization, while also gazing upon the awe-inspiring skyscrapers and smart cities that grace our modern landscape.

As we navigate through the annals of history, let’s imagine ourselves as explorers of the time, discovering the foundations laid by our ancestors, the innovation of modern engineers, and the role of visionary companies like Rudra Infratech in shaping our megacities.

The Indus Valley Civilization: Where It All Began

Our adventure begins with a leap back to the Bronze Age, around 3300 BCE, to the cradle of one of the world’s earliest urban civilizations, the Indus Valley Civilization. This enigmatic ancient civilization boasted impeccable urban planning, with advanced sewage systems, well-structured streets, and fortified cities. Oh, what marvels they were! Their cities like Mohenjo-Daro and Harappa are testimonies to their engineering prowess, a heritage that still echoes in the urban infrastructure of our modern cities.

The Roman Empire: Pioneers of Engineering Wonders

As our time-travelling machine catapults us to ancient Rome, we find ourselves in the heart of one of the most powerful empires in history. The Romans were true pioneers of engineering wonders, constructing an extensive network of roads, aqueducts, and awe-inspiring architectural feats like the Colosseum and the Pantheon. Their awe-inspiring creations not only stood the test of time but also laid the groundwork for future civilizations to build upon.

Medieval Marvels: Blending Art and Architecture

The Middle Ages may have been marked by feudal systems and castles, but it was also a time when engineering met artistry in breathtaking harmony. Think of the magnificent Gothic cathedrals that soared towards the heavens, weaving stone into intricate lace-like designs. These majestic structures showcased humanity’s quest for divinity and the incredible craftsmanship of the era. Imagine the pride that the skilled builders of those times felt as they saw their work rise and touch the skies.

The Industrial Revolution: Unleashing the Power of Machinery

Fast forward to the 18th and 19th centuries, when the world was thrust into the Industrial Revolution. With steam engines chugging along and machinery transforming production, infrastructure development took a giant leap. Railways crisscrossed continents, bridges spanned mighty rivers, and factories transformed urban landscapes. As we look back, we can’t help but wonder how these advances laid the foundation for the bustling metropolises we cherish today.

Modern Marvels: Skyscrapers and Beyond

Welcome to the era of dizzying heights and architectural ingenuity – the modern world. Our metropolises now boast skyscrapers that seem to touch the heavens. Cities like Mumbai, Delhi, and Bangalore are bejewelled with shimmering towers, each telling a story of ambition, resilience, and innovation. But behind the towering facades, there lies a silent hero – Rudra Infratech.

Unveiling the Silent Hero: Rudra Infratech

As we step out of our time machine, we are greeted by the awe-inspiring sight of Rudra Infratech’s bustling construction site, where our team toils with unwavering determination, building the dreams of millions. As a pioneering company, our vision for excellence and commitment to quality have made Rudra Infratech synonymous with progress in shaping modern India’s infrastructure. With immense pride, we witness our company’s transformative impact, leaving a lasting legacy across the nation. Our dedicated team continues to drive forward, fueled by the passion to create a better tomorrow, one landmark at a time. Together, we are the driving force behind the nation’s development and prosperity.

Building the Future, Stone by Stone: M Sand and Aggregates

At the heart of our company, Rudra Infratech lies an unwavering dedication to supplying high-quality construction materials like M sand and aggregates. As the building blocks of our cities, these essential components strengthen the foundations of every majestic structure that adorns the skyline. Our team’s meticulous focus on sustainability and eco-friendly practices sets us apart as we strive not just to construct buildings but to nurture a greener, cleaner tomorrow. With pride in our work, we are not merely shaping infrastructure, but also fostering a legacy of responsible development. Together, we are architects of a brighter, more sustainable future for generations to come.

Smart Cities: Paving the Way for the Future

As we journey further into the future, “Smart Cities” dominate conversations, and marvels where urban ingenuity converges with human needs. At Rudra Infratech, we stand at the forefront, providing vital infrastructure that brings these cities to life. Our team’s passion for innovation drives us to contribute to intelligent traffic management, energy-efficient buildings, and cutting-edge technologies that adapt to the needs of inhabitants. With pride in our company’s role, we help create urban marvels that think, respond, and evolve, shaping a brighter tomorrow for all. As the architects of these smart cities, we embrace the responsibility to build a sustainable and connected world for generations to come.

The Future Beckons: A Shared Vision

Our expedition through time has revealed the fascinating tapestry of India’s infrastructure evolution. From the well-planned streets of the Indus Valley Civilization to the towering skyscrapers of today, every step on this journey has been a testament to human progress. And in every era, Rudra Infratech has played an integral role, in nurturing growth and constructing dreams.

As we bid farewell to our time-travelling adventure, we are filled with awe and inspiration. The future beckons with its promise of even more awe-inspiring achievements, and it’s reassuring to know that Rudra Infratech will continue to be at the forefront of this transformation. So let us, the architects of the future, continue to build, innovate, and dream of the grand cities that will define generations to come.

In the end, dear reader, the evolution of infrastructure is not just a journey of bricks and mortar but a testament to our relentless pursuit of progress, our ability to dream, and our commitment to leaving a lasting legacy for the world. Let us build, with Rudra Infratech by our side, a future where our cities stand tall, not just in concrete and steel but in the hearts of every citizen who calls them home.

About Rudra Infratech-

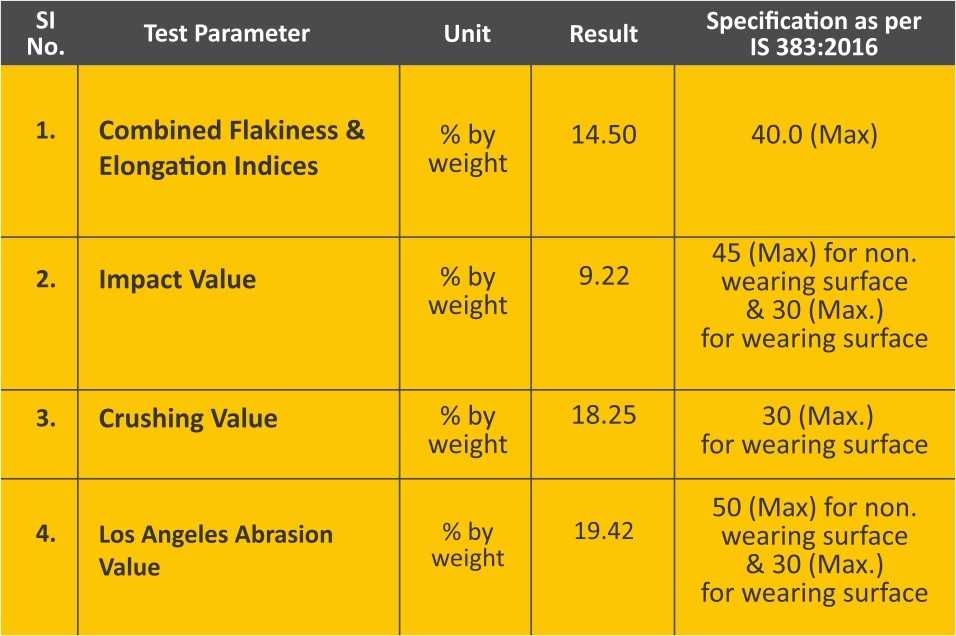

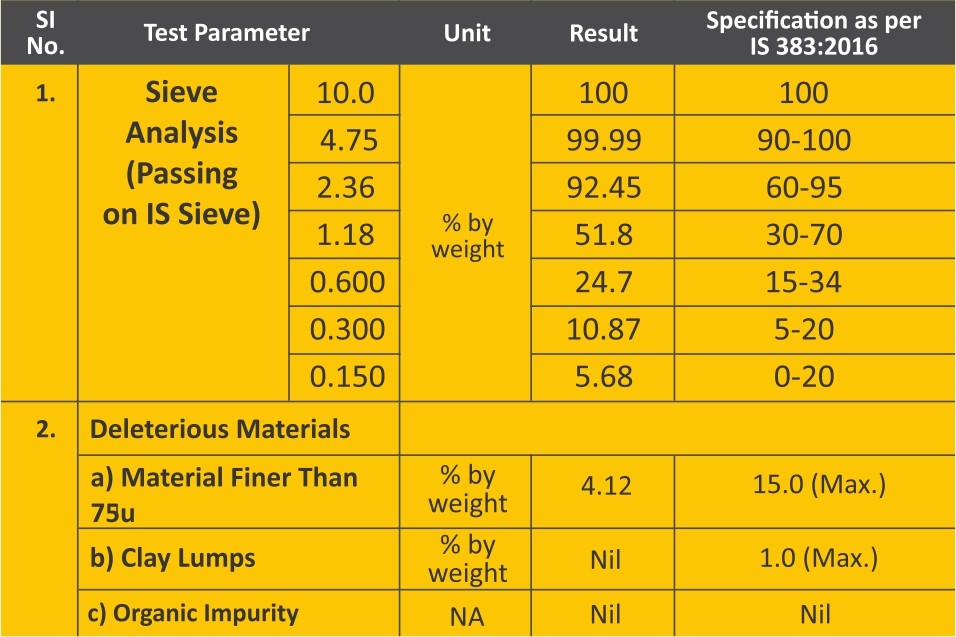

We are a leader in the mining and crushing of Aggregate, Machine Sand, Wet Mix Macadam and Granular Sub Base, with a 9,00,000 metric ton per annum capacity in Udaipur. Our state-of-the-art 3-stage crushing plant and sand washer ensure the roundness and ease of flow for pumping concrete. Our M Sand and Aggregates are the best in the market, providing a sustainable alternative to river sand. Our M-Sand is uniform and strong, produced by crushing hard stones into small, angular, washed, and graded particles. Our Aggregates, made from natural sources, provide the foundation for construction, conforming to industry standards of elongation and flakiness index.

To know more about us, visit: https://rudrastonecrushers.com/

For more such content, visit our LinkedIn Page: https://www.linkedin.com/company/rudra-infratech/