How does Rudra Infratech conduct its Quality Checks?

#RudraInfratech is a renowned company that produces and supplies M-sand and Aggregates in Udaipur. Quality is at the core of everything that Rudra produces. The company is committed to providing clients with construction materials of the highest possible quality. At various stages of the production process, #RudraInfratech conducts rigorous quality checks to guarantee that its products meet the highest quality standards.

How does Rudra ensure the quality of their products?

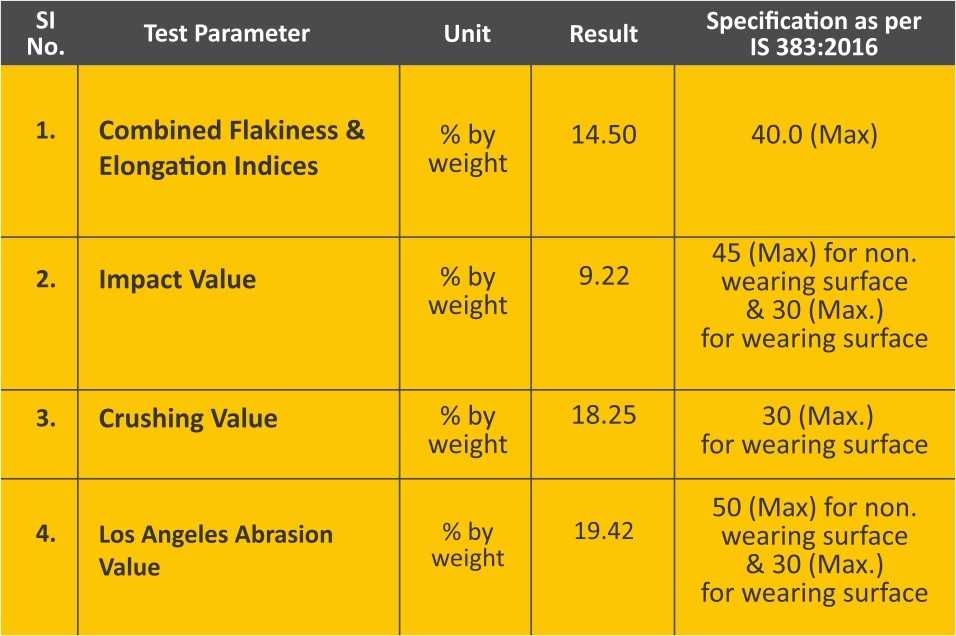

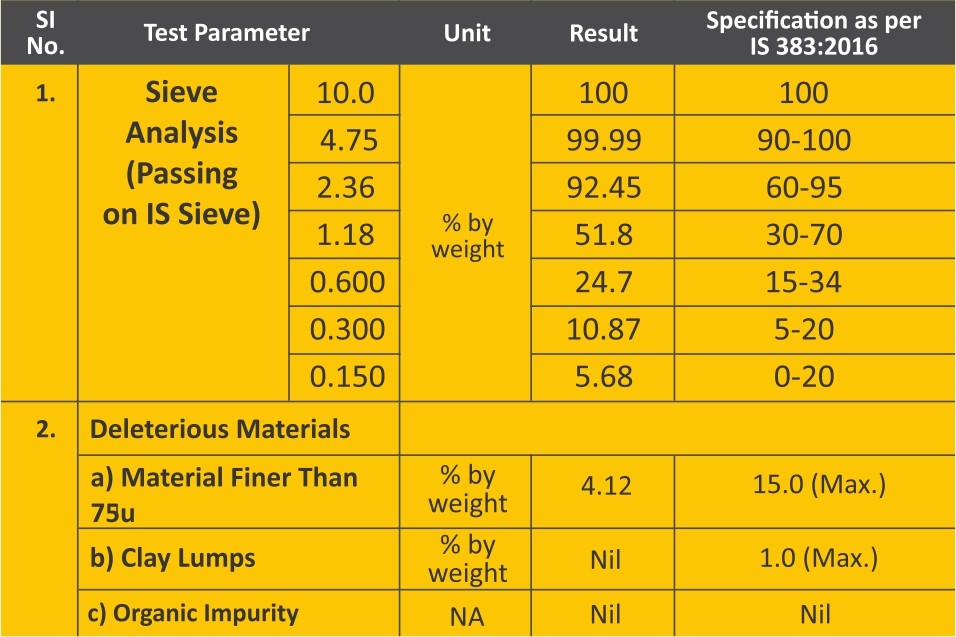

Rudra Infratech’s quality speaks for itself. At each stage of the production process, Rudra conducts regular quality checks to ensure that their products meet the required standards. Below are the quality reports for Rudra Infratech’s M-Sand & Aggregates:

What are the checks that are conducted by Rudra to maintain this quality?

Rudra conducts a range of quality checks including:

- Quality control at the production stage – Quality control begins at the production stage at #RudraInfratech. To produce its building materials, the company makes use of cutting-edge machinery and equipment. In order to guarantee that each piece of equipment is working at its absolute best, it is regularly serviced and inspected. The trusted suppliers of the raw materials used in the production process meet Rudra Infratech’s stringent quality requirements.

The company’s quality control team checks the materials regularly during the production process to make sure that they meet the requirements. The team uses a range of testing equipment, including sieve analysis, to check the size and shape of the aggregates and M-sand. The team also checks the moisture levels, texture and grading of the materials to ensure that they meet the required standards.

Rudra Infratech’s quality control team is comprised of experienced experts who have extensive knowledge of the construction materials industry. They are able to spot potential problems and take corrective action to ensure that the materials being produced are of the highest quality.

2. Quality Control at the Storage Stage – Once the construction materials have been produced, they are stored in a controlled environment to avoid contamination and degradation. #RudraInfratech has a separate storage facility to store construction materials safely.

The quality control team at the company checks the stored materials on a regular basis to make sure that they haven’t been damaged or contaminated in any way. The team checks the material’s moisture content and texture to make sure they still meet the requirements.

3. Quality control at the delivery stage – The quality control team at #RudraInfratech checks the construction materials one last time before they are delivered to the client to make sure that they meet the requirements. To ensure that the materials are in top condition, the team examines their size, texture, moisture, content and grading.

Additionally, #RudraInfratech guarantees that the materials arrive at the customer on time and in sufficient quantities. Additionally, the company has a dedicated team of customer service representatives who are available to address any questions or concerns that customers may have.

The commitment to quality control at #RudraInfratech extends beyond the production and delivery procedures. Additionally, the company provides its customers with technical support and guidance to assist them in selecting the appropriate building materials for their projects. The company’s technical team has extensive knowledge of the construction materials industry and is able to provide expert advice on the use and application of their products.

What are the equipments used by #RudraInfratech for quality testing?

Rudra uses a range of equipment for getting the quality tested on a regular basis on various parameters such as the Flakiness index, impact value, and crushing value. These parameters are evaluated by:

- Sifters and screens

- Moisture meters

- Grinding and crushing machines

- Digital weighing scales for exact estimation of the materials

How does #RudraInfratech ensure customer satisfaction?

Rudra strives to provide products and services that meet the needs of its customers and places a high value on customer satisfaction. They offer prompt delivery, competitive pricing and excellent customer support to ensure their customers are happy and satisfied with their products and services.

#RudraInfratech is dedicated to providing its customers with construction materials of the highest possible quality. At each stage of the production process, the company conducts rigorous quality checks to ensure that the material it uses meets the required specifications. #RudraInfratech is able to provide construction materials of the highest quality thanks to cutting-edge machinery, equipment, and testing methods.

The organization’s obligation to quality control and consumer loyalty has made it perhaps the most trusted name in the development of the materials industry. Rudra Infratech’s customers can rest assured that they are getting the best products and services available.

About Rudra Infratech-

We are a leader in the mining and crushing of Aggregate, Machine Sand, Wet Mix Macadam and Granular Sub Base, with a 9,00,000 metric ton per annum capacity in Udaipur. Our state-of-the-art 3-stage crushing plant and sand washer ensure the roundness and ease of flow for pumping concrete. Our M Sand and Aggregates are the best in the market, providing a sustainable alternative to river sand. Our M-Sand is uniform and strong, produced by crushing hard stones into small, angular, washed, and graded particles. Our Aggregates, made from natural sources, provide the foundation for construction, conforming to industry standards of elongation and flakiness index.

To know more about us, visit: https://rudrastonecrushers.com/

For more such content, visit our LinkedIn Page: https://www.linkedin.com/company/rudra-infratech/